Case Study: How a global composites supplier prevents losses and elevates quality with Collo

By Collo on Sep 24, 2025

With Collo's liquid process intelligence, this global composites manufacturer prevented batch failures worth € 80K – 150K each, achieved faster troubleshooting, and significantly reduced material waste. The solution delivered immediate ROI through improved production stability, early detection of quality deviations, and data-driven decision-making that transformed their resin manufacturing process.

About the Company

A global manufacturer of advanced plastic and composite materials supplies high-stakes industries including aerospace and automotive. Operating at industrial scale with highly complex resin formulations, quality control, process monitoring, and traceability are mission-critical. Even subtle variations can trigger costly setbacks, production inefficiencies, and customer dissatisfaction.

THE CHALLENGE

Undetectable variations with serious consequences

The company faced recurring challenges with inconsistent resin quality across R&D and production environments. With one bad raw material batch costing approximately €10K directly, the stakes were high—but the real impact was far more severe. When production costs, increased waste costs, and labor were factored in, the total financial effect of a single faulty raw material batch reached €80K–150K.

Traditional lab testing and manual inspections lacked the sensitivity to detect subtle but impactful material deviations. Bad quality raw material batches were typically discovered only after the full production cycle, making prevention nearly impossible. For a company supplying aerospace and automotive industries, faulty final products cannot enter the delivery pipeline due to significant penalty costs, making reputation damage an even greater concern than immediate financial losses.

"We had to rely heavily on lab tests and manual observations, which took time and often came too late in the process to react efficiently."

— Senior Process Engineer

The challenge intensified due to the complexity and variety of chemicals in use, making late-stage detection nearly impossible and root cause analysis extremely difficult. The team desperately needed real-time visibility and better methods to monitor homogeneity throughout the mixing process.

THE SOLUTION

A smarter way to see

The company discovered Collo through peer recommendations and targeted research into advanced monitoring technologies. Attracted by the promise of inline, real-time insights without operational disruption, they immediately initiated a laboratory trial.

Collo’s breakthrough technology combines electromagnetic field (EMF) sensors with AI-powered analytics to create unique “liquid fingerprints” for real-time process monitoring. By measuring multiple variables simultaneously, the system produces multi-dimensional fingerprint profiles that can distinguish even very similar resin formulations and detect the smallest quality variations.

Collo’s machine learning algorithms then analyze the data in real time, correlating sensor signals with physical properties to enable predictive process intelligence. This continuous data collection provides laboratory-level precision, delivered instantly during production.

"The promise of real-time, actionable data was very appealing. We needed something that could integrate seamlessly into our environment and provide clearer visibility into our processes."

— Senior Process Engineer

Unlike other monitoring tools they had tested and ultimately rejected, Collo delivered a completely new approach to process intelligence—combining exceptional sensitivity with user-friendly operation.

Real-time process intelligence in action

Initially deployed in the laboratory environment, Collo enabled the team to monitor resin homogeneity in real time with unprecedented precision, detect material fluctuations during production runs before they became critical, compare samples from different process points without operational interference, and adjust mixing times and fine-tune process parameters based on live feedback.

"We used it for monitoring resin homogeneity and identifying material fluctuations. It helped us catch and correct inconsistencies early in the process."

— Process Technician

In one critical incident, Collo's data revealed a raw material deviation that traditional methods had completely missed. Armed with this early insight, the team responded quickly and prevented a complete batch failure worth €120K.

THE RESULTS

Immediate Impact, lasting benefits

Since implementing Collo's technology, the transformation has been remarkable. The Collo analyser provides continuous visibility into resin homogeneity that was previously impossible, while AI-powered analytics automatically flag potential quality issues before they impact production.

Collo detected subtle variations within seconds, compared to traditional lab tests that required hours or days. This immediate feedback enables rapid adjustments to mixing parameters and timing, preventing quality deviations before they propagate through entire batches.

Key improvements achieved:

- More stable production and fewer quality deviations

- Faster, smarter decision-making based on real-time trends

- Reduced material loss and production downtime from early detection

- Immediate process improvements that started paying back the investment

- Significant reduction in batch failures from undetected material variations

"It saved us from wasting material and production time, and we've dramatically improved overall consistency. The investment paid for itself within the first quarter."

— Process Technician

Building on these remarkable results, the company is now preparing to trial Collo's inline analyzer technology, targeting continuous quality control from tank to final transfer.

Ready to transform your process?

See how Collo's liquid process intelligence can help you prevent costly batch failures, reduce material waste, and make faster, data-driven decisions in your operations.

Stay informed — subscribe to our newsletter

Related stories

Help visitors get the basic idea within a few seconds, so they understand what this section is about.

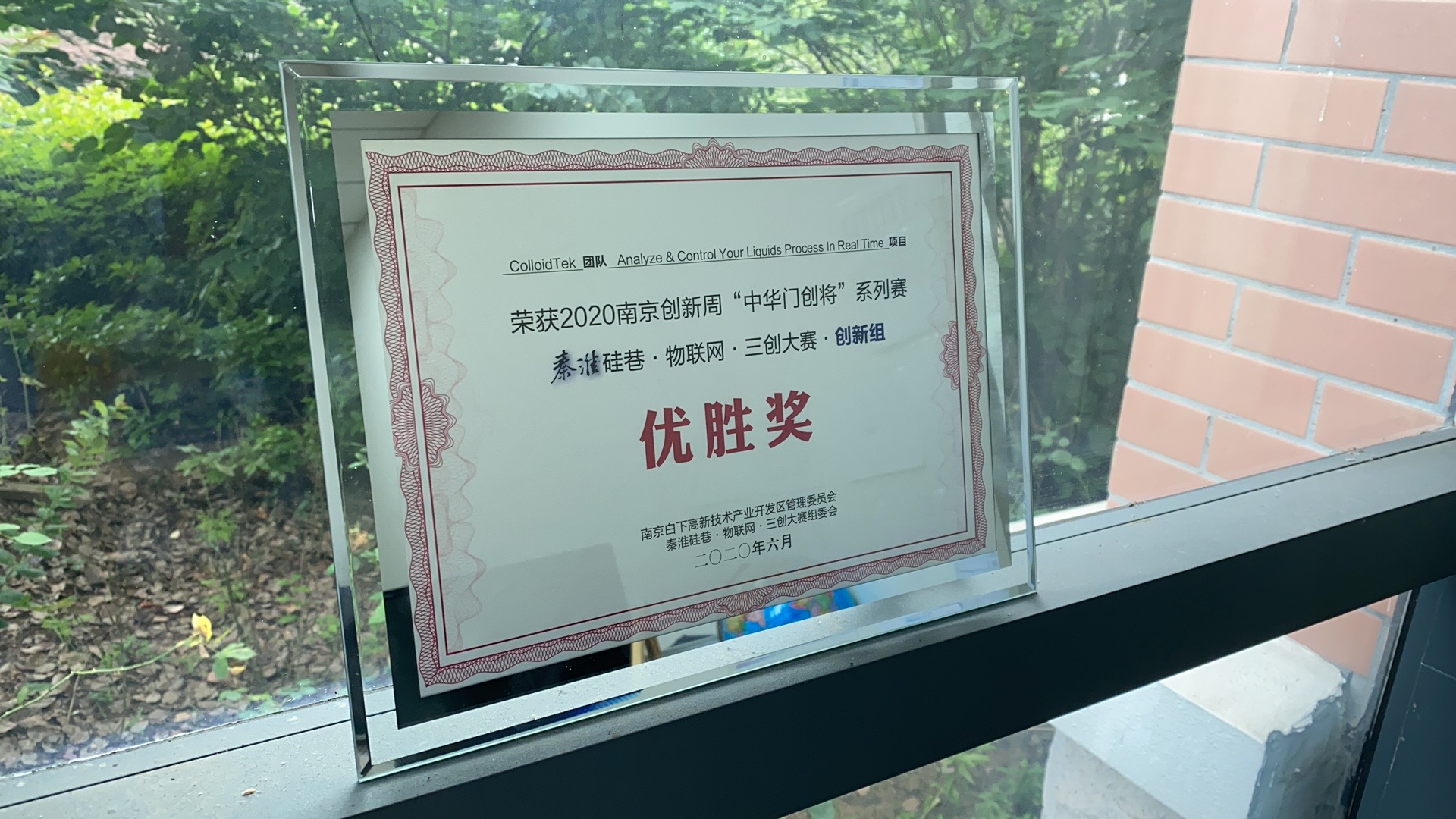

ColloidTek wins the Prize of Excellence in Start-ups Innovation during Nanjing Tech Week.

ColloidTek selected as one of the Top 25 most innovative Nordic Cleantect start-ups of 2020