Greener plants, stronger profits

Minimize product losses, reduce energy consumption, and unlock your plant’s full potential with liquid process intelligence.

Hidden costs of dairy process inefficiencies

Dairy producers face pressure to drive efficiency and meet tough sustainability targets. But behind every unoptimised process lies a quiet cost draining resources, spiking emissions, and eroding margins.

Even a 1% raw milk loss can cost over 2.6M € annually. Add energy waste, CO₂ emissions, and growing wastewater fees, and the impact becomes clear: inefficiency is your silent competitor.

Discover the true impact of inefficiencies. Calculate how much product your plant is losing and what it’s costing you.

Let’s turn every drop into value

With precise, actionable insights and seamless automation, we transform everyday inefficiencies into measurable value. Our technology empowers dairy producers to eliminate waste, boost profitability, and drive sustainability.

Stop losing product, start maximising profit

Every push-out can quietly drain profits. Lost dairy product is ”double whammy”, you lose the product and then pay extra in the wastewater treatment—but not on our watch.

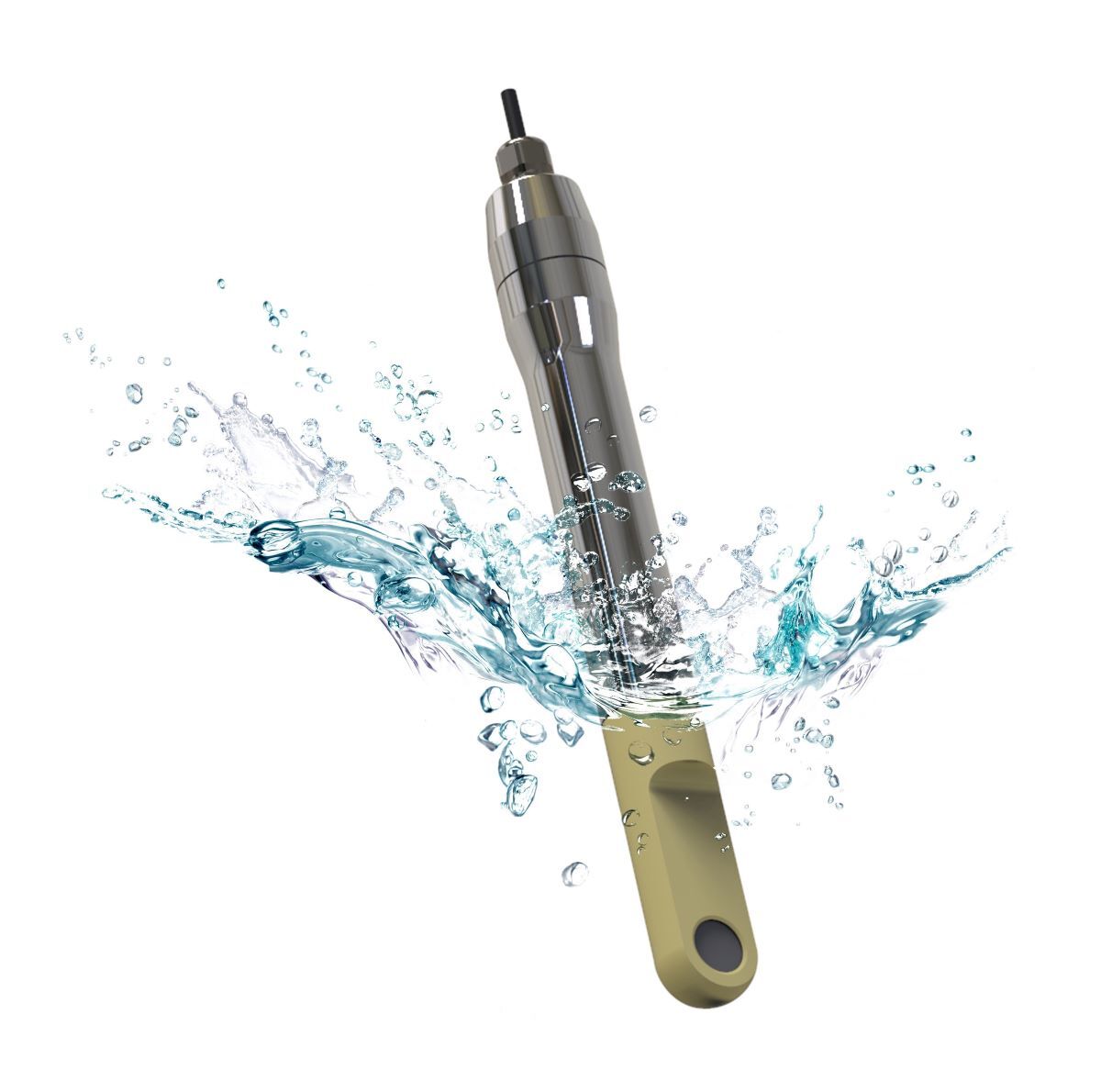

Collo pinpoints hidden losses with real-time precision, instantly transforming waste into measurable value.

Cut product loss, improve yield, and hit your sustainability goals with confidence. With Collo, invisible waste becomes visible profit.

Overcleaning is overcostly

More cleaning isn't better—smarter cleaning is. Collo’s CIP optimisation gives clear, instant visibility into every rinse and chemical cycle. Shorten cleaning durations, slash unnecessary chemical, water, and energy use, and reclaim valuable production hours every week. Effortless efficiency, measurable savings—every time.

Instant decisions, maximum efficiency

Real-time data isn't useful if it doesn't trigger action. LiquidIQ integrates seamlessly with your plant’s automation, turning complex data into automatic, precise adjustments. Enhance productivity, yield, and sustainability instantly.

Key features of our solutions

Collo is built for all dairy liquids — from raw milk to whey, cream, and yogurt. Continuously analysing liquid composition, immediately detecting even the slightest change or deviation. Seamlessly integrated into your existing plant setup, Collo delivers insights without interrupting production. With precise, actionable data at your fingertips, optimising your process becomes effortless, empowering you to boost efficiency, cut costs, and strengthen your sustainability impact.

Pushout optimization

- Detect product/water interfaces in real-time

- Prevent product loss with precise valve control

- Prevent excess wastewater treatment costs

CIP Optimization

- Ensure performance and cleanness

- Reduce chemical & water waste

- Optimize rinse cycle length & cleaning efficiency

- Save energy and reduce hot water usage

Sustainability & ESG Compliance

- Achieve regulatory goals & reduce CO₂ emissions

- Improve water and chemical efficiency

- Stay within environmental permit limits

- Lower wastewater costs

Seamless Integration to Automation

- IoT-enabled sensors with machine learning insights

- No major infrastructure changes required

How our customer boosted efficiency and gained significant savings

Valio’s Joensuu plant made significant savings annually by optimising their cream line production with Collo.

Seamless integration with your dairy plant

Collo is engineered for the real world — built to integrate effortlessly with your existing systems and validated to perform under real production conditions without disrupting operations. From milk and cream to cheese and yogurt, Collo technology is tested, traceable, and ready to go from day one.

Every Collo analyzer goes through structured field trials, rigorous factory acceptance testing, and full compliance checks before shipment. This ensures that each device is reliable, compliant, and fully documented — ready to support audits and deliver consistent performance from the start.

- No major infrastructure changes needed

- Works with all dairy production lines

- Built-in diagnostics, remote support & lifecycle traceability included

-

CE-marked and food-contact compliant (EC No 1935/2004, FDA)

Different products for different dairy challenges:

ProcessIQ

Runs continuously to monitor all CIPs and pushouts, identifying losses and providing automation tuning recommendations. Essential for multi-product facilities with frequent changeovers.

LiquidIQ

Real-time process intelligence for automation. Provides new signals like cream fat-%, product/water mix-%, or CIP stage completion that you integrate into your automation for closed-loop control.

Collo Lab Analyzer

Portable, real-time liquid analysis for quality control, research, and product development - wherever you need it.

Frequently Asked Questions

Dairy Optimization

Collo works with all dairy liquids including:

- Raw milk (all fat percentages)

- Skim milk and whole milk

- Cream (all fat contents, including heavy cream)

- Buttermilk and cultured products

- Yogurt base and fermented dairy

- Cheese whey and permeate

- Protein concentrates (WPC, WPI)

- Milk powders in liquid form

- Lactose solutions

- Ice cream mix

The technology is universal — from the thinnest whey to the thickest cream, opaque or clear, Collo creates an accurate liquid fingerprint.

Collo provides three key compliance benefits:

1. Real-time Quality Verification

- Continuous monitoring detects deviations immediately

- Creates timestamped quality records automatically

- Provides audit trails for every production batch

2. CIP Validation

- Documents that cleaning cycles achieve required cleanliness

- Proves rinse water meets specifications

- Eliminates manual sampling and testing delays

3. Traceability

- Every batch has complete liquid fingerprint record

- Integration with MES/ERP for full traceability

- Supports recalls with precise batch identification

Compliance standards supported:

- HACCP

- FSSC 22000

- BRC

- IFS Food

- ISO 22000

Collo integrates via standard industrial protocols:

PLC/SCADA Integration:

- OPC-UA, Modbus TCP, Profinet

- Direct integration with Siemens, Allen-Bradley, Schneider, ABB controllers

- Real-time data exchange (liquid fingerprint → automation decisions)

MES/ERP Integration:

- REST API for business system integration

- Batch records and quality data export

- Integration with SAP, Wonderware, Rockwell FactoryTalk

Installation:

- Inline sensor installation: 1-2 days per line

- Control system integration: 2-3 days

- Training and commissioning: 1 week

- Total deployment: 2-3 weeks for typical dairy plant

No disruption: Installation during planned maintenance shutdowns, no production stoppage required.

Yes. Collo platform provides centralized monitoring across:

- Multiple production lines (milk, cream, yogurt, etc.)

- Multiple facilities (standardize operations across plants)

- Multiple countries (benchmark regional performance)

Collo complements rather than replaces laboratory analyzers:

Key differences:

| Feature | Collo | NIR/FTIR |

|---|---|---|

| Measurement | Real-time, inline | Batch, offline |

| Response time | <1 second | Minutes to hours |

| Maintenance | Zero drift, self-cleaning | Regular calibration needed |

| Cost | Lower CAPEX | Higher CAPEX |

| Application | Process control | Quality verification |

Best use together:

- Collo for real-time process optimization and loss prevention

- NIR/FTIR for detailed composition analysis and final product certification

- Collo catches problems immediately; lab confirms root cause