Liquid process intelligence

Real-time intelligence that cuts product loss, boosts efficiency, improves the bottom line and makes sustainability pay off - all with one simple, scalable solution.

Trusted by industry leaders

Collo wins World Beverage Innovation Award 2025

At Drinktec 2025, Collo was awarded the World Beverage Innovation Award in the Processing/Production Innovation category. This recognition celebrates our breakthrough sensor technology that captures the complete liquid fingerprint — turning invisible losses into measurable gains.

From dairy to beverages, Collo is redefining what’s possible. More yield, less waste. Smarter decisions — right when they matter.

Inefficient processes

are costing a fortune

Small inefficiencies in dairy and beverage production can drain resources, increase waste and CO₂ emissions, and eat into profits.

Without real-time visibility, critical processes like pushouts, CIP, and changeovers lose product, waste water, and rely on guesswork. Traditional sensors can’t measure liquid behavior directly - but Collo can.

Our liquid process intelligence delivers the clarity to cut losses, optimize timing, and reduce environmental impact while boosting yield and lowering costs.

Discover the true cost of inefficiencies. Calculate how much product your plant is losing and what it’s costing you.

The intelligence powering the world’s most efficient plants

Transforming dairy efficiency

From intake to packaging, Collo delivers real-time visibility to cut losses, optimize pushouts, and protect every drop - cutting costs, boosting margins, and enabling sustainable production.

Peak performance in every drop

Whether it's juice, soft drinks, or plant-based products, Collo gives you real-time intelligence to minimize waste, maximize output, and protect every batch.

Turn data into action with Collo

Collo transforms your liquid processes by translating real-time data into clear actions - cutting waste, saving resources, and improving your bottom line.

Pushout optimisation

Detect product transitions with real-time precision - recover more, waste less, and boost profitability and sustainability in one smart move.

Real-time process control

Automatically optimize flow rates, transitions, and timings with instant, data-driven adjustments — no delays, no guesswork, just smarter control.

CIP optimisation

Shorten cleaning cycles with real-time control - using less water, fewer chemicals, and cutting downtime without overcleaning.

Connecting liquid intelligence to automation, efficiency, and innovation

ProcessIQ

Intelligence you can act on. Your continuous process health monitor. Analytics dashboards and expert recommendations showing where to tune your automation. Never miss losses in CIPs or pushouts.

LiquidIQ

Real-time process intelligence for automation. New signals your automation has never had before. Enable state-based automation for unprecedented control accuracy. Replace time/flow-based guessing with actual process state.

Collo Lab Analyzer

Explore applications on your own. Portable solution for testing use cases, feasibility studies, and R&D projects. Perfect for customers who want to explore liquid process intelligence independently.

Impact dairy industry europe

Discover the true impact of inefficiencies. Calculate how much product your plant is losing and what it’s costing you.

How leading producers boost efficiency and cut costs with Collo

Collo helped Valio’s Joensuu plant cut significant annual costs by optimizing cream line efficiency and eliminating hidden losses.

Liquid process intelligence, built for the future

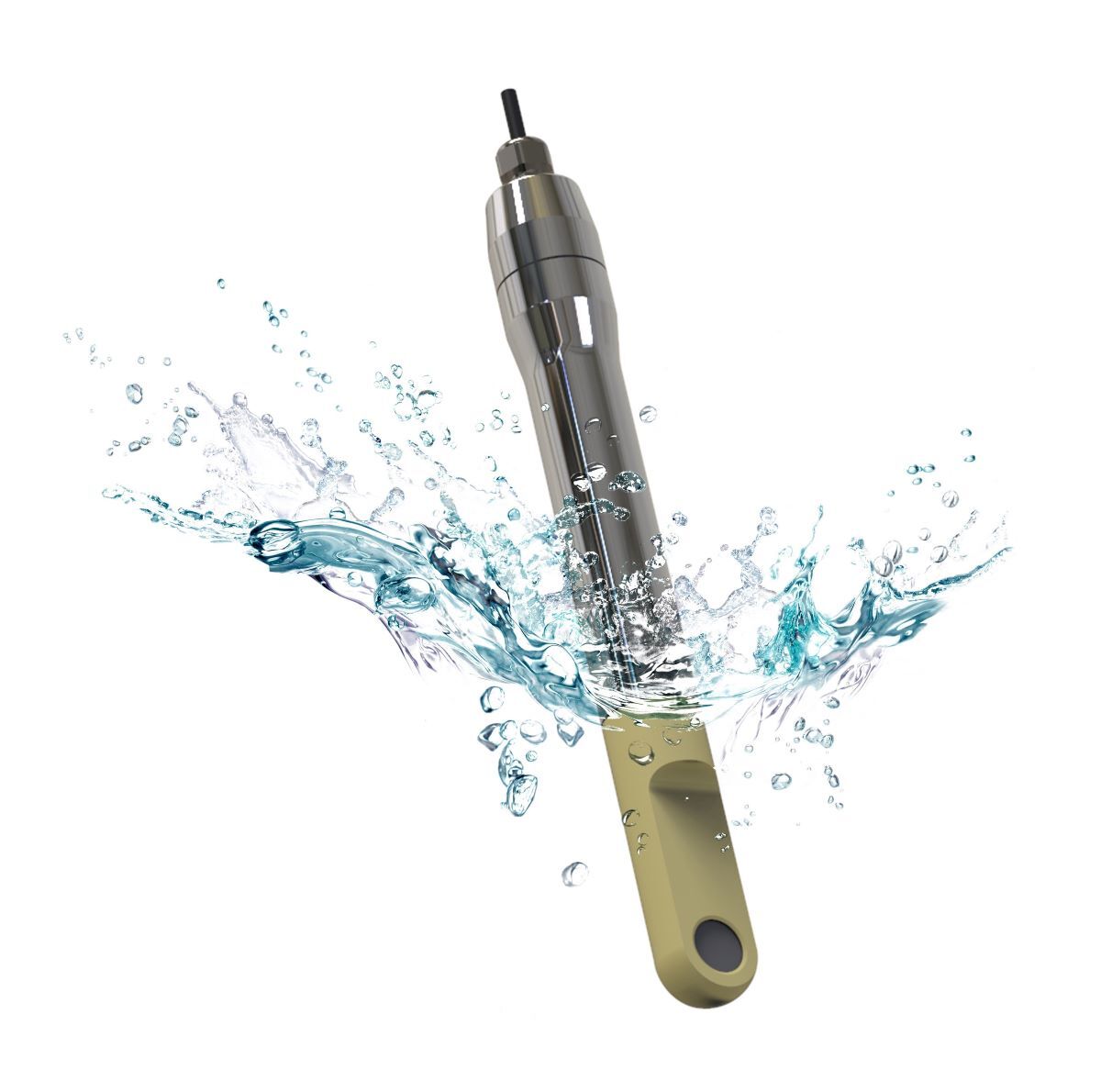

The core of Collo’s innovation is our sensor technology - a highly accurate system that detects changes in the physical properties of liquids in real time and directly within industrial processes.

Collo’s sensors are suitable for liquids of any type - from simple to highly complex, thick or thin, clear or opaque - allowing for detailed monitoring of composition, consistency, and process behavior.

Paired with our adaptive software, these real-time sensor signals are correlated with historical and operational data to deliver actionable insights - enabling optimization of pushouts, CIP cycles, batch consistency, and remote diagnostics.

Smart production starts with Collo

Collo is a Finnish deep-tech company on a mission to make liquid processing smarter, greener, and more profitable. At Collo, we help Dairy and Beverage producers turn every drop into value.

Tech, trends & events driving smarter production

Stay ahead with the latest in liquid process innovation in your industry. From tech breakthroughs to real-world examples, explore how Collo is helping the dairy and beverage industry increase profitability, optimize performance, reduce waste, and build the smart factory of tomorrow.

Real-time process intelligence comes to brewing

Our article on liquid process intelligence for breweries was recently published in…

Why 'One more dashboard' won't fix your CIP process

Every few months, another vendor arrives at the plant with impressive analytics, b…

The true cost of product losses in dairy manufacturing: A data-driven analysis

European dairy processors handle approximately 160 million tonnes of raw milk annu…