Pioneering the liquid process intelligence

Collo—the intelligent solution designed to optimize, simplify, and sustain your liquid processing. Harnessing cutting-edge radio frequency sensor technology and sophisticated analytical methods to eliminate guesswork and redefine industry standards.

A new era in liquid process intelligence

Introduction to Collo’s technology

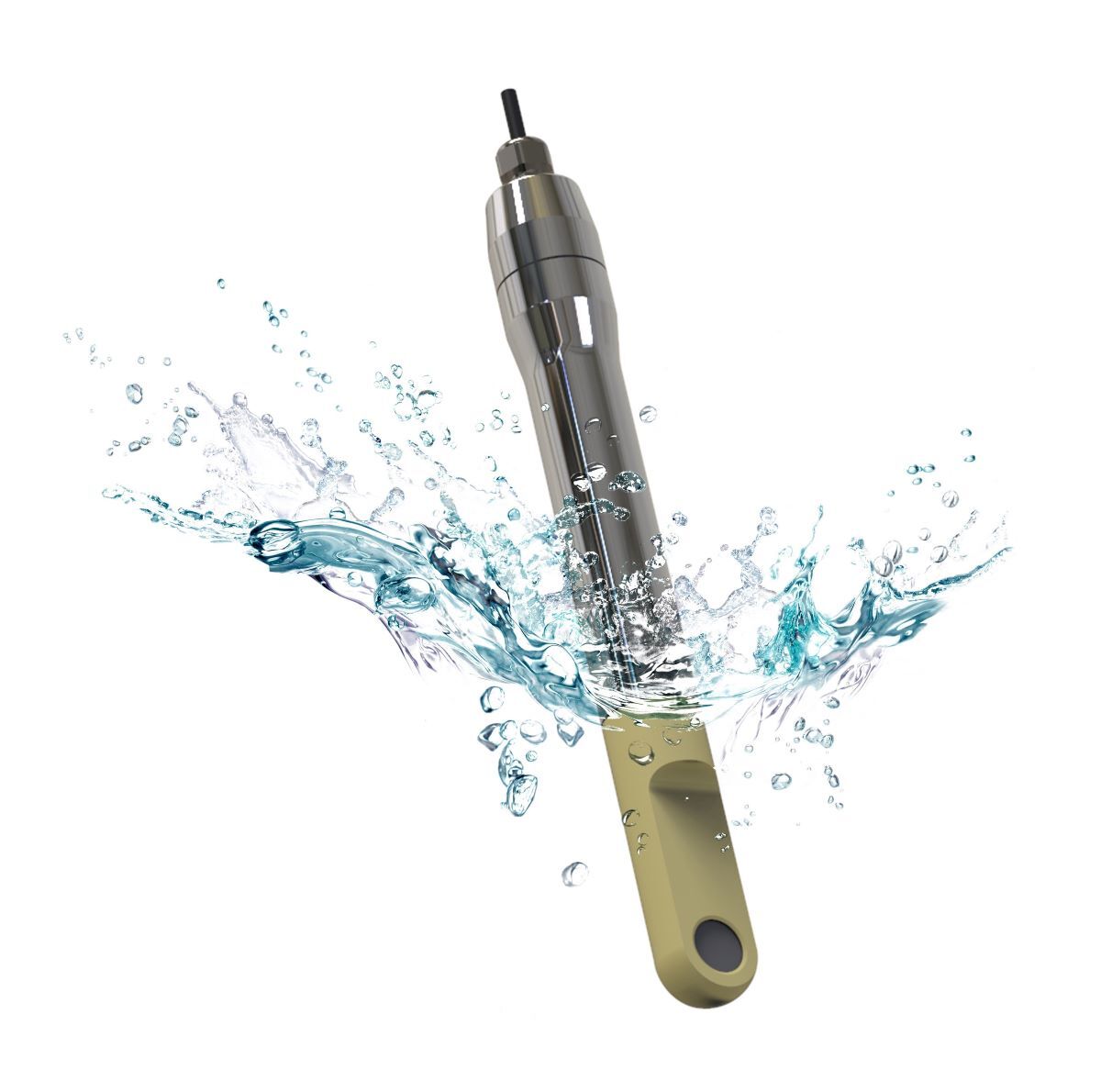

Innovative sensor

At the core of our innovation is Collo’s advanced sensor technology, engineered for continuous, real-time measurement of liquid properties. Universally applicable across all liquid types — from the thickest concentrates to the clearest solutions — it detects even the smallest changes, regardless of chemical complexity. Enabling precise tracking of liquid parameters and applications such as:

- Phase Detection: Detecting phases or phase transitions in emulsions, suspensions, or crystallization processes.

- Chemical Concentration Monitoring: Measuring the relative composition of ingredients in multi-component liquid systems.

- Impurity Detection: Recognizing non-dissolved particles.

Intelligent platform

Collo’s platform continuously learns from operational data, improving accuracy and efficiency over time. By correlating sensor data with historical trends and external process variables, it enhances:

- Pushout Optimization: Optimizing pushouts to reduce product loss, product dilution and waste

- Remote Maintenance: We can monitor our sensors remotely, and take action online to solve issues, or to run software updates.

- Batch Consistency: Minimizing variability across production runs by adjusting parameters in real-time.

- Energy and Resource Efficiency: Optimizing CIP (cleaning-in-place) cycles, reducing water and chemical usage without compromising hygiene standards.

Science behind Collo

At the heart of Collo lies an advanced RF resonator that emits a directional electromagnetic field (EMF) into the liquid. As this field interacts with the liquid’s molecules and particles, subtle changes in chemical composition and phase dynamics distort the field uniquely.

Collo measures these changes through real-time frequency sweeps and generates an electromagnetic spectrum response specific to the liquid. Proprietary algorithms then interpret this data into actionable insights, providing instant feedback on critical physical parameters such as dissolved chemicals, solids concentration, particle size, and more.

Liquid fingerprint

Collo’s technology accurately identifies and measures complex liquid compositions by recognizing unique electromagnetic signatures, creating a liquid “fingerprint”. Once calibrated, Collo effortlessly monitors variations in chemical composition, particle sizes, and phase distributions, giving you granular control and ensuring consistent quality and performance.

Why Collo outperforms other technologies

Unlike optical or conductivity sensors, Collo’s proprietary technology delivers high-resolution, multi-parameter data regardless of the liquid’s opacity, colour, or viscosity. This enables detection of fine-scale variations in chemical composition and structural changes.

Collo’s sensors require minimal calibration and no maintenance downtime, significantly reducing operational costs compared to optical, electrochemical, or electrical sensors.

Smart sensor

Our sensor detects almost any change in a liquid by measuring the shifts in its dielectric properties — which respond to both chemical and physical changes in the liquid.

Real-Time Data Collection

Machine Learning Powered Analytics

Automated Adjustments

Transforming food and beverage industries with process intelligence

ProcessIQ

Intelligence you can act on. Your continuous process health monitor. Analytics dashboards and expert recommendations showing where to tune your automation. Never miss losses in CIPs or pushouts.

LiquidIQ

Real-time process intelligence for automation. New signals your automation has never had before. Enable state-based automation for unprecedented control accuracy. Replace time/flow-based guessing with actual process state.

Collo Lab Analyzer

Portable, real-time liquid analysis for quality control, research, and product development - wherever you need it

Frequently Asked Questions

If you still have question, please feel free to contact us.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi.