Quality, innovation, and speed

Portable liquid intelligence for quality control teams, researchers, and product developers — to detect, react, and optimize faster than ever.

Built for breakthroughs, not bottlenecks

In modern labs and production environments, every delay, missed change, and error has a price. In liquid analysis, waiting for results or missing critical shifts is no longer an option. The difference between success and costly setbacks comes down to what you can see and when you can act.

- Quality Control: Risking batch rejections, recalls, or customer complaints because deviations aren’t caught in time.

- Research Teams: Struggling to capture dynamic, real-time reactions needed to drive discoveries and breakthroughs.

- Product Developers: Wasting cycles on trial-and-error instead of real-time validation during formulation.

Old methods can’t keep pace. You need full visibility — instantly.

Quality, research, and innovation

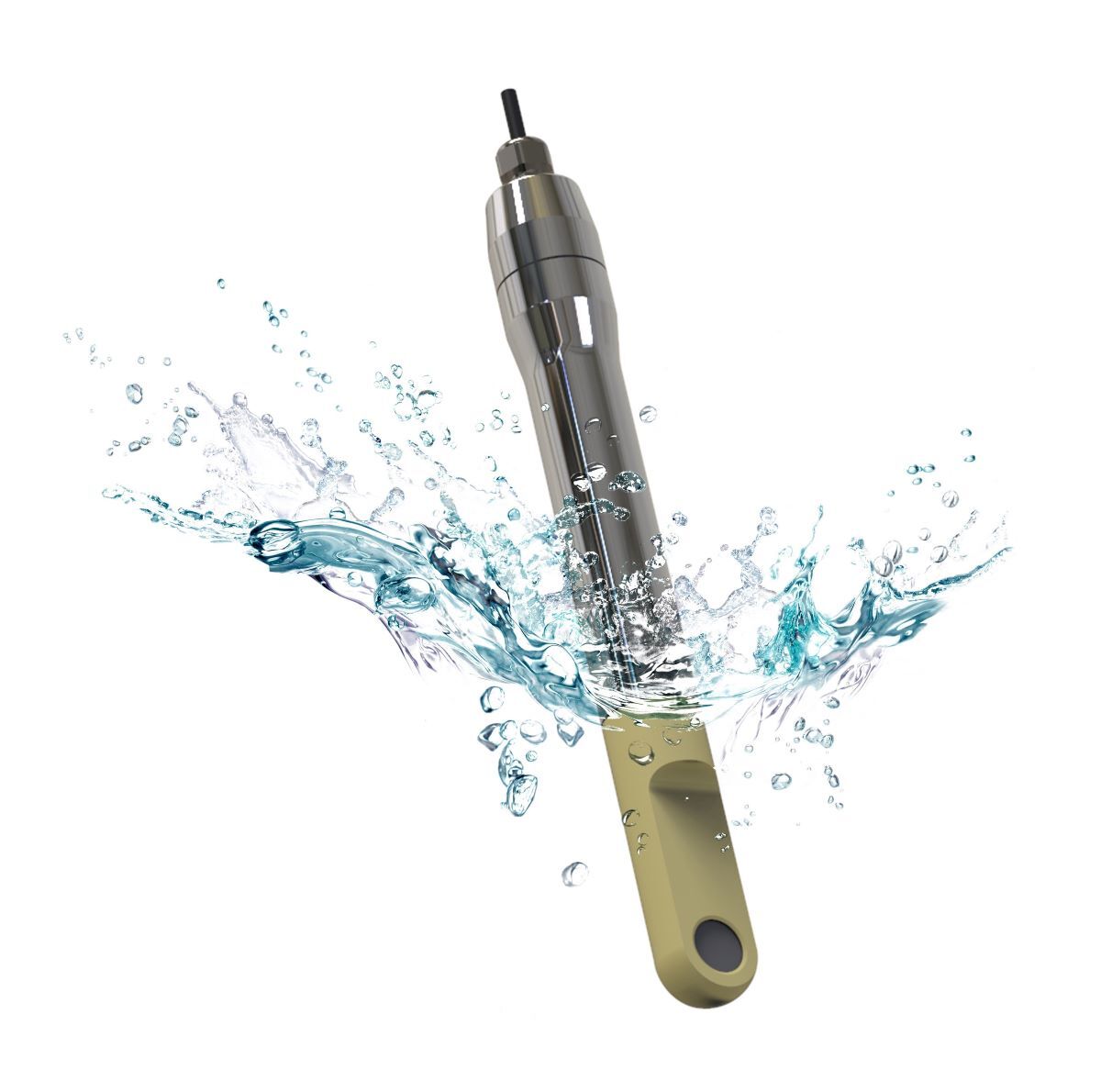

Collo Lab Analyzer changes the game. Instead of reacting after the fact, teams can now catch deviations the moment they begin, keeping production on track and quality assured.

In research environments, every subtle reaction becomes visible, accelerating discoveries and unlocking insights faster than traditional methods allow. During product development, real-time feedback replaces guesswork — helping new ideas take shape faster, with fewer trial cycles and greater confidence.

When precision and speed matter most

To deliver detailed liquid insights with the versatility, durability and intelligence that modern labs and production teams demand.

Explore the features that set Collo Lab Analyzer apart:

EMF-Based Measurement:

Versatile Application

Advanced Analytics

Seamless integration. Instant results.

Plug into your automation with zero hassle.

Collo Connect is designed to fit effortlessly into your operations — no heavy lift, no downtime. Our experts work directly with your teams to ensure smooth deployment, security compliance, and optimal setup. You get live, actionable data feeding into your systems — fast, reliable, and future-proof.

Included in the project:

- Inline installation via hygienic Tri-Clamp

- Simple cabling: quick-connect M12 to RJ45

- Standard 230V AC / 50 Hz power supply

- No manual calibration —intelligence ready out of the box

- Secure network options:

- Integrate directly into your internal LAN

- connect securely through a Collo-managed external link

Quality Control

Track all quality requirements with one analyzer, respond faster to quality issues, and prevent contamination from hazardous materials.

Laboratory & Research

Advance research with new, detailed insights from even hard-to-measure reactions and liquids, screen raw materials before production, and enjoy seamless data management.

Product Development

Speed up product testing and development with immediate insights and real-time results.

Designed user-friendly

The Collo Lab Analyzer is engineered for easy integration into existing laboratory and production workflows.

User-Friendly interface: Intuitive LabUI software for straightforward operation.

Portable design: Facilitates on-site analysis without the need for complex setups.

Comprehensive support: Backed by Collo’s expert team for implementation and ongoing assistance.

Frequently Asked Questions

If you still have questions, please feel free to contact us.

Collo measures virtually all liquids — transparent or opaque, thin or thick — including emulsions, suspensions, and slurries.

Temperature up to 90 °C. Pressure up to 10 bar. Collo is resistant to CIP chemicals and most industrial fluids. For corrosive or solvent-heavy chemicals, please contact us to verify compatibility.

Sensor connects via 1.5” Tri-Clamp. Data cable is M12 to RJ45 with stsandard 5/10/15 meter options (extendable up to 30 meters). ECU is powered via 230V AC / 50 Hz outlet.

Collo does. We monitor, maintain, and update the system remotely — so you don’t have to.

Yes. Collo provides real-time data to SCADA or DCS systems and can control process steps via Modbus TCP or OPC UA.

Temperature: 0–90 °C. Pressure: up to 10 bar. Minimum pipe size: DN50.

It can connect via your internal network or a secure external Collo-managed line. We work with your IT and automation teams to ensure safe integration.

Monitoring, diagnostics, software updates, and support.

A suitable inline pipe location (DN50+), power source (230V), and a route for data cable. Our team will assist throughout setup.

Yes. Collo complies with EU Directive 1935/2004, Finnish Decree KTM 268/1992, and FDA CFR Title 21.