A beverage producer cut CIP time by 23% and saved half a million

A major European beverage producer was rinsing perfectly clean pipes with perfectly clean water. For 15 unnecessary minutes. Every cleaning cycle. 250 times a year. They suspected it. But suspicion doesn't change procedures.

Data does.

ABOUT THE CUSTOMER

This established European beverage manufacturer operates multiple high-volume production lines with frequent product changeovers, running approximately 250 CIP cycles annually on one line. They face the same pressures as most food and beverage producers: rising water costs, tightening sustainability regulations, increasing energy expenses, and growing consumer demand for environmental responsibility.

CHALLENGE

Conservative cleaning built on guesswork

The plant processes diverse product lines requiring thorough cleaning between batches. With decades of conservative practices built into standard operating procedures, the team knew their time-based CIP programmes included significant inefficiencies but lacked the data to optimise safely.

Three critical blind spots kept them stuck:

Limited sensor visibility

Existing conductivity sensors provided basic readings but couldn't detect when cleaning was actually complete. Turbidity meters offered additional data, but neither sensor could detect both product residues and chemical residues with the precision needed to optimize each phase.

Time-based programs

Every CIP cycle followed the same predetermined recipe: pre-rinse for 8 minutes, caustic circulation for 15 minutes, final rinse for 20 minutes. These conservative programs hadn't changed in years, built on assumptions rather than real-time conditions.

No endpoint detection

The plant manager watched operators standing by CIP systems, seeing sensors hit zero whilst timers kept running. "We're definitely running longer than we need to, but how do we prove it? And more importantly, how do we know when we've cleaned enough?"

Without clear answers, they remained trapped in "better safe than sorry"—wasting time, water, chemicals, and production capacity every cycle.

SOLUTION

Real-time intelligence replaced guesswork

Collo's CIP Optimisation solution provided the breakthrough they needed. Rather than following static programmes regardless of actual conditions, the solution detects when each cleaning step is truly complete.

The customer started with a focused approach: a Collo Insights project on a single production line. This evaluation phase quantified exactly how much waste existed and where improvement opportunities were hiding, providing the data-driven business case needed before scaling the solution.

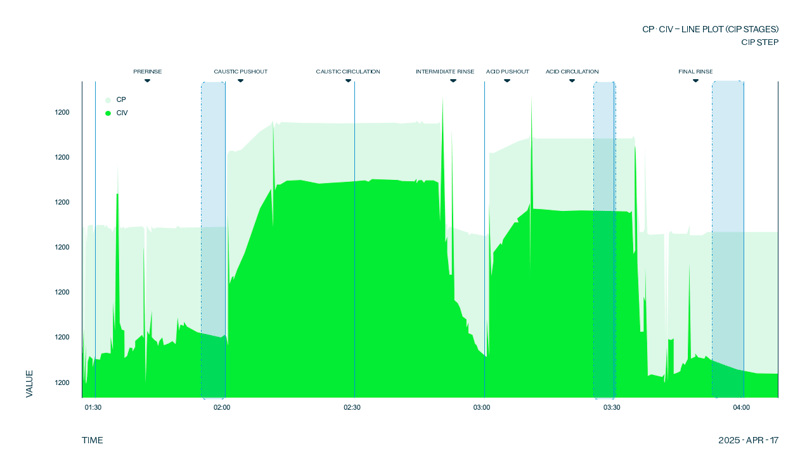

Collo's team integrated the analysers to provide real-time visibility into each rinse and chemical cycle. Multiple CIP cycles were monitored to establish comprehensive baseline data, revealing exactly where resources were being wasted.

Detect

Monitor key parameters of CIP cycles, including interfaces, cleaning time, and chemical usage.

Analyse

Analyse measurements to detect water/chemical/product interfaces. Quantify loss areas and transform data.

Report

Visualise each CIP cycle stage. Identify opportunities to reduce cleaning time, optimise chemical usage, and cut water consumption.

Implement

Apply the insights to optimise CIP cycles. Validate and build business case for scaling across the plant.

Collo Insights provided analytics that identified specific optimisation opportunities across all cleaning phases, revealing the gap between when traditional sensors suggested completion and when cleaning was actually complete.

Every optimisation recommendation was validated by the customer's team through standard sensory testing protocols, hygienic compliance verification, and product quality assessments. The customer maintained full control over implementation decisions, ensuring all changes met their safety and quality standards.

RESULTS

The true cost of over-cleaning—from one line alone

The data revealed substantial waste hidden in their "conservative" approach, with the most dramatic discovery in the final rinse phase—15 minutes of unnecessary rinsing every single cycle.

Time savings per CIP cycle

- Pre-rinse: 4.8 minutes saved

- Caustic circulation: 5.1 minutes saved

- Final rinse: 15.1 minutes saved

- Total: 26.4 minutes saved (23% reduction)

Additional savings of 1.4 minutes came from optimising transition times and other minor phases throughout the cycle.

Annual business impact from one production line

With 250 cycles annually on a single line, the optimisation delivered transformational results:

- Production capacity gained: 6,500 minutes annually

- Water consumption reduction: 1.552 million litres annually

- Potential reduction in product losses: 25% annually

- Estimated monetary savings: €541,667 based on optimal capacity utilization

- Payback period: Rapid ROI through resource savings and increased production time

“Half a million euros from one production line. When you see numbers like that, you realise how much guesswork actually costs. Collo turned suspicion into savings we can measure.”

Operations Director

Operational transformation

The implementation delivered more than efficiency, it provided confidence and control. Operators gained clear visibility into every cleaning stage. Plant managers received actionable data they could trust. Every resource became optimised for maximum value whilst maintaining rigorous safety and quality standards.

Collo's detailed measurement provided the proof needed to optimise with confidence and the business case to scale across the entire plant.

Still running time-based CIP programs?

You're over-cleaning. The question is by how much. Our CIP Optimisation solution shows you exactly where your cycles can be optimised without compromising quality.

From one line to full-scale impact

With half a million saved from a single line, the plant-wide impact represents millions in annual savings, providing the business case needed to scale the solution across all production lines.

The proven approach: start with one line, validate the results, then roll out plant-wide. Every additional line optimised multiplies the impact whilst minimising implementation risk.

Ready to discover your optimisation potential? Use our CIP Savings Calculator below to calculate how much time, water and money your plant could save with Collo.

Frequently Asked Questions

If you still have question, please feel free to contact us.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi.

Ready to stop over-cleaning?

Start your journey towards smarter decisions, reduced waste, and a greener future today.