Seeing what flow meters can't: Unlocking €300k in savings

A European dairy plant processing 245 million litres annually had industry-standard automation, yet tests kept showing diluted product. Flow meter inaccuracies were masking 1.3-2.28% dilution. Collo revealed what traditional measurement missed—seconds of mistiming multiplying into major losses.

ABOUT THE CUSTOMER

This European dairy plant processes 245 million litres of raw milk annually, specialising in cream processing and dairy concentrates. The facility ran industry-standard automation, magnetic flow meters with backup timers, automated controls, and comprehensive mass balance monitoring. All best practice for modern dairy operations.

Yet despite this solid technological foundation, the plant faced persistent quality issues their existing systems couldn't explain.

THE CHALLENGE

The data said fine, the product said otherwise

Pushout sequences look straightforward on paper. In practice, they're deceptively complex. The plant's magnetic flow meters did exactly what they were designed to do: control pushouts with backup timer security. Material losses were tracked through mass balance calculations where flow meter data played the central role.

On paper, everything looked perfect. Mass balance showed no losses or dilutions. Pushout timing appeared accurate. The process seemed to run efficiently.

Laboratory testing revealed something different: the final product was consistently diluted.

The root cause: Flow meter inaccuracy in mass balance

At the heart of the issue sat a blind spot in measurement. The plant relied on mass balance calculations built on magnetic flow meters assumed to provide accurate volume measurements. Investigation revealed actual measurement variance significantly exceeded expected tolerances, creating systematic errors throughout production tracking.

Mass balance calculations appeared normal. No losses or balanced flows. Meanwhile, product was being lost and diluted throughout the process. The flow meters fed incorrect data directly into the balance system, creating a false sense of accuracy whilst actual losses remained invisible.

The challenge of multi-stage processing

Dairy processing involves multiple transformation stages where material composition changes continuously. Raw milk separation, standardisation, and subsequent processing steps each require precise measurement to track material flows accurately. When flow meters at any of these points provide inaccurate data, the entire mass balance system's accuracy suffers.

Error multiplication at scale

The plant's operational complexity amplified the problem. Products move through the system multiple times during processing, and each pass through an inaccurate measurement point compounds the error. With dozens of measurement points throughout the plant, small individual inaccuracies multiplied into substantial material losses.

At industrial volumes processing 245 million litres annually, these compounding measurement errors translated into significant product waste and financial impact, all whilst the measurement system reported normal operations.

"Our automation was telling us everything was perfect, mass balance looked great, no alarms, flow meters reading normally. But we kept seeing diluted product."

Plant Operations Manager

SOLUTION

Solving the unseen

The operations team deployed Collo analyzers at two critical points where losses had the greatest impact: the cream line and raw milk reception. Nine analyzers were installed for Collo Insights service:

Three in cream processing. Before pasteurization, after pasteurization, and during tank filling.Six in raw milk reception. Monitoring the lines feeding the plant’s raw milk silos.

The installation process was straightforward, supported by standardized inlets and simple setup.

Data collection and analysis

During the monitoring period, each pushout moved approximately 20,000 litres of product, with 450–1,000 pushout events recorded per location. Collo analysers captured high-resolution data on pushout sequence interfaces, enabling clear analysis of timing and product transitions.

The dataset revealed actual process behaviour and highlighted the scale of inaccuracies caused by flow meter limitations.

Detect

Monitor pushout sequences at critical points. Cream processing and raw milk reception to capture high-resolution data on product-water interfaces.Analyse

Analyse measurements to detect precise timing of product-water transitions. Identify systematic valve timing offsets and random errors. Quantify dilution across 450-1,000 pushout events per location.

Report

Visualise timing discrepancies for each pushout event. Show where valves close too early or too late, allowing water to enter product streams. Calculate dilution percentages and financial impact.

Implement

Apply insights to correct valve timing across the plant. Eliminate systematic offsets and reduce random variation. Validate savings and build business case for plant-wide optimization.

“When we saw the Collo data compared to our flow meter readings, it was like turning on the lights. ”

Process Engineer

RESULTS

Errors multiplying into major losses

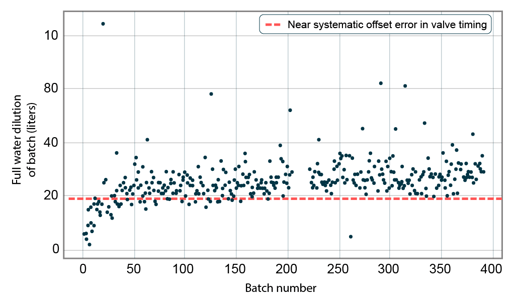

The analysis revealed two critical issues undermining process efficiency: a near-systematic valve timing offset combined with random timing errors and variation.

Consistent offset and random errors

In several locations, valve operations were consistently offset by a few seconds. On top of this offset, random timing errors occurred. Whilst small at each point, these errors appeared across multiple pushouts, multiplying the overall impact.

Collo Insights revealed batch dilution from consistently offset valve timing error.

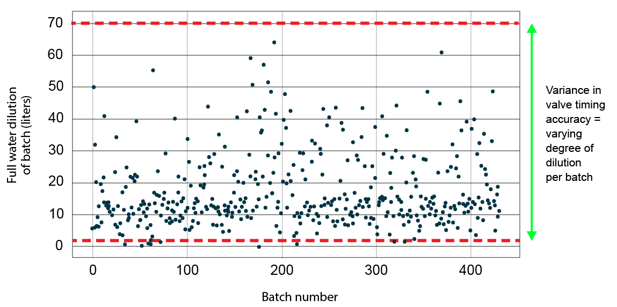

Random timing variation

In other areas, pushout durations varied widely from event to event, sometimes ending too soon, sometimes running too long. This variability made it impossible to correct the problem with simple timer adjustments or basic control logic.

Collo Insights revealed batch dilution due to variance in valve timing accuracy

Process behavior insights

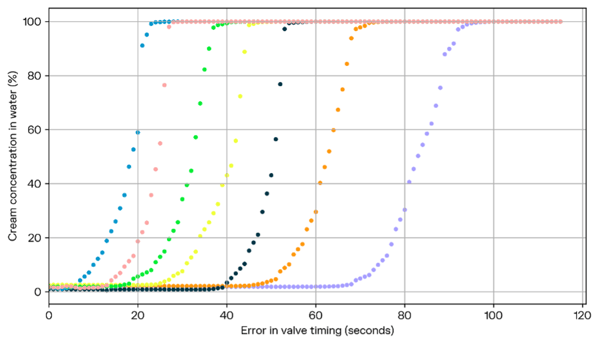

Collo data revealed that flow meter inaccuracies caused incorrect volume readings that led to miscalculated valve timing, allowing water to enter the product stream during pushouts.

In some cases, when valves closed while pipes contained water, clean water continued flowing into product tanks for up to 40 seconds, diluting the final product.

Variations in pushout valve timing errors revealed by Collo Insights.

The Financial Impact

Across monitored pushouts, dilution ranged from 1.3% to 2.28% of total product volume. The underlying issue was clear: inaccurate flow meter data feeding into mass balance calculations. Because the volume measurements were inconsistent, the system miscalculated valve operation timing.

As a result, water often entered the product stream during pushouts. In some cases, when valves closed whilst pipes were still full of water, clean water continued flowing into tanks for up to 40 seconds. This led to diluted product, unnecessary losses, and higher downstream costs.

Annual Savings: €300,000+

Process improvements delivered substantial savings through:

- Reduced product dilution and reprocessing costs

- Improved yield and material recovery

- Decreased water consumption and wastewater treatment

- Eliminated excess logistics costs from transporting water-diluted product

- Reduced laboratory testing and quality control overhead

- Decreased production replanning costs

- Annual savings of over €300,000

"The €300K number really opened everyone's eyes. We thought we had a small quality issue, but it turned out to be a major financial problem. "

Plant Manager

Beyond the Initial Scope

The analysis didn't stop at cream processing. Once Collo Insights exposed hidden dilution losses, the team extended monitoring to adjacent areas, uncovering further inefficiencies in raw milk handling and nano-whey concentrate processing. These losses had gone unnoticed for years, masked by inaccurate flow meter data and mass balance assumptions.

With Collo, the plant gained the visibility needed to correct critical errors, optimise processes, and unlock substantial savings.

Want to see what Collo Insights might reveal in your process?

Frequently Asked Questions

If you still have question, please feel free to contact us.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Integer tincidunt. Cras dapibus. Vivamus elementum semper nisi.

Ready to start optimising?

Start your journey towards smarter decisions, reduced waste, and a greener future today.